(TS) Technical

Garment issue systems for textile service comapnies

Garment distribution/delivery systems can be seen as the connection for workwear between the customer/end user and the laundry. A distribution system was formerly used as a logistic solution for work wear with the intention to save costs on labour and garments. These functions are further extended since a system today is seen as an extension…

Read MoreCamera monitoring for quality control

An Advanced Automatic Linen Inspection and Quality Control Scanning System. The Mobics Ai Scan automatically detects and recognizes stains, tears, and holes to assure production and delivery of high quality bed and table linens. It can also classify, sort, and count flatwork based on size, colour, patterning, and/or logos. All parameters are touch screen customizable…

Read MoreHanging systems for textile services

If you are considering a logistical reorganization of your laundry, you will do well to be guided by the latest developments. There are considerable savings to be achieved for your business. New technologies can offer significant improvements. Depending on the type of laundry, specific innovations can be selected. On the cutting edge of technology and…

Read MoreEfficiency and textile care during the drying process

Introduction The increasing number of processed goods is also creating an increased diversity of items and materials. Dryers, ironers, and finishers must cover this diversity and combine high output and evaporation performance with low energy consumption and textile care. Practical tests in a laundry, where the textile damage after 50 cycles of washing and drying…

Read MoreEnergy efficiency in dewatering and drying

Drying The traditional way of drying uses hot air to evaporate the water in the textile. The hot air is blown into the dryer which rotates to let the air access every part of the laundry. Drum rotation is one of the methods to increase the efficiency of the drying process. A lot of energy…

Read MoreXeros Sbeadycare; the revolutionary concept for laundry

Through extensive research Xeros has developed a revolutionary concept of cleaning. In addition to the Sinner factors, water, temperature, chemicals, and time, beads are used to clean clothes. In fact, one of the factors of the Sinner circle, mechanical action, is increased by the beads. The mechanical action is increased through the contact of polymer…

Read MoreSMARTEX Miracle High Speed Washer Extractors

The design of Smartex Miracle series, those being manufactured by Tolkar, has emanated from actual problems encountered by the users during the washing process. The major principle considered during the design of Smartex Miracle machines was to achieve the desired processes by using the simplest and most effective mechanical design possible. After long research and…

Read MorePowerTrans – the continuous batch washer generation which combines output and flexibility

Introduction Today a laundry is confronted with challenges resulting from social developments of globalization, individualization of the customers, changes in demographic, and shortage of natural resources. The overall number of linen to produce is increasing, as well as the diversity of articles, materials, finishing processes, customer demands, and costs for energy, water, and the textiles.…

Read MoreInnovation in Design; the Milnor way to do laundry with PulseFlow technology

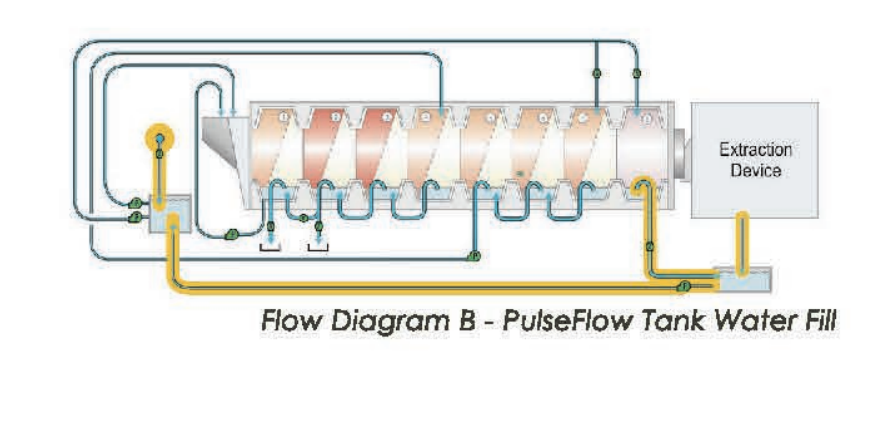

Pellerin Milnor has developed a revolutionary, patent-pending concept, called PulseFlow Technology CBW washer, which has been successfully implemented in various locations worldwide. The technology involves a new and innovative use of water and chemistry in a top transfer Milnor CBW washer. Multiple independent third party laboratory tests all verify that healthcare linen in a Milnor PulseFlow…

Read More